Roles of CDMOs, CROs & CMOs:Drug Substance vs. Drug Product

Tânia Marante | Posted on July 08, 2025

If you’ve ever wondered how your medicine makes it from a lab idea to a product on the pharmacy shelf, there’s a high chance that a CDMO was involved. CDMO stands for Contract Development and Manufacturing Organization. These are specialized companies that help pharmaceutical businesses develop and manufacture drugs. On Pharmaoffer.com, we help connect those companies with trusted partners.

But what exactly do CDMOs work on? The work is generally divided into two main categories: drug substances and drug products.

Table of contents

Drug Substances vs. Drug Products: What’s the Difference?

Drug substances are the core active ingredients that provide the therapeutic benefit. These are typically produced through complex chemical or biological processes. On the other hand, drug products are the final forms that patients use, such as tablets, creams, or injectables, created by combining drug substances with other components.

What brings these categories together is their shared goal: delivering safe and effective treatments to patients. While drug substances form the ‘foundation’, so to speak, providing the core therapeutic effect, drug products make that foundation accessible and usable in the real world, assuming the form of tablets, eye drops, creams, syrups, or injectables, depending on the treatment need. CDMOs often specialize in one or both areas, and together with CMOs (Contract Manufacturing Organizations), they ensure medicines are developed and manufactured efficiently from molecule to market.

Drug Substances (Developed by CDMOs and CROs)

This is the actual active ingredient in a medicine—the part that has a therapeutic and healing effect. Often referred to as “API” (Active Pharmaceutical Ingredient), drug substances are the foundation of any medicine.

Here are the main types:

Small Molecule APIs

These are the most common type of drugs—chemical compounds that are small enough to enter cells and have a direct therapeutic effect.

Think of everyday pills like aspirin or ibuprofen.

Biologics

Unlike small molecules, biologics are made from living organisms. These include proteins, antibodies, and vaccines.

They’re often used in more complex therapies like cancer treatment or autoimmune disorders.

Peptides

Peptides are short chains of amino acids (the building blocks of proteins). They’re used in treatments ranging from metabolic diseases to cancer.

Commonly used in injectable treatments, they play a critical role in managing conditions like diabetes (e.g., liraglutide) and hormone-sensitive cancers (e.g., buserelin).

Oligonucleotides

These are short DNA or RNA molecules used in cutting-edge gene therapies. They can help regulate, repair, or replace faulty genes.

You’ll find them in advanced rare disease treatments, such as nusinersen for spinal muscular atrophy or eteplirsen for muscular dystrophy.

Natural Extracts

These are substances derived from plants or animals. While often associated with herbal remedies, many mainstream drugs also come from natural sources.

For instance, paclitaxel (used in chemotherapy) comes from yew tree bark, and digoxin (used for heart conditions) is extracted from the foxglove plant.

Intermediates

Before a final API is made, several chemical steps are involved. The materials created along the way are called intermediates.

These are often invisible to the final user but absolutely essential in the synthesis of complex drugs, like antivirals and antibiotics.

Fine Chemicals

These are high-purity chemicals used as building blocks for APIs. Their complexity and precision make them critical to pharmaceutical development.

Take benzyl chloride, for example, often used in producing antihistamines, or ethyl acetate, a versatile solvent in many synthesis steps.

Cell and Gene Therapy

These represent some of the most advanced drug types, involving the use of living cells or genetic material to treat diseases at their root cause.

Modern breakthroughs like Zolgensma for spinal muscular atrophy or Luxturna for rare eye conditions are redefining how we approach medicine at the genetic level.

Drug Products (Manufactured by CMOs)

Once the drug substance is ready, it needs to be formulated into a product that patients can actually take. This is where CMOs—Contract Manufacturing Organizations—step in.

Here are the common formats:

Oral Solid Products

These include tablets and capsules—what most people think of when they hear “medicine.”

Examples: Paracetamol tablets, ibuprofen capsules, multivitamin tablets.

Liquid Oral Products

Syrups or suspensions—typically used for children or people who have trouble swallowing pills.

Examples: Cough syrup, paracetamol suspension, antacid liquids.

Semi-Solid Products

Creams, gels, and ointments applied to the skin fall into this category.

Examples: Hydrocortisone cream, antifungal ointments, acne treatment gels.

Ophthalmic Products

These are sterile solutions or suspensions made for the eyes, such as eye drops.

Examples: Artificial tears, antibiotic eye drops, glaucoma treatments.

Nasal Products

Sprays or drops administered through the nose. Useful for allergies or nasal congestion.

Examples: Saline nasal spray, decongestant drops, corticosteroid nasal sprays.

Inhalation Products

Used mainly for asthma or respiratory conditions, these are delivered directly to the lungs through inhalers or nebulizers.

Examples: Asthma inhalers (e.g., salbutamol), COPD inhalers, nebulized antibiotics.

Biologic Products

This refers to any formulation of biologics into a final dosage form—whether that’s an injection, spray, or oral product.

Examples: Insulin injections, monoclonal antibody therapies, growth hormone sprays.

Cell and Gene Therapy

These products are often delivered through advanced methods like infusions or direct injections. They’re tailor-made for specific patients.

Examples: CAR-T cell therapies, gene-editing treatments, autologous stem cell infusions.

Sterile Injectables

These are medicines administered through injections. They must be completely sterile and are often used in hospitals.

Examples: Vaccines, antibiotics like ceftriaxone, oncology drugs like paclitaxel.

Final Thoughts

Understanding the basics of drug substances and drug products helps demystify how medicine is made—and the crucial role CDMOs and CMOs play in that process.

From developing active ingredients in a lab to producing sterile injectables ready for patient use, these organizations are behind almost every step of modern pharmaceutical manufacturing. They help pharmaceutical companies scale up production, ensure regulatory compliance, manage complex supply chains, and get treatments to market faster—all while maintaining the highest quality standards.

At Pharmaoffer, we connect companies looking for CDMO partners with trusted, certified service providers across these categories. Whether you’re working with a small molecule or a cell therapy, we help bring pharma products to life.

Interested in learning more about specific categories? Stay tuned for our upcoming blog series that dives deeper into each one.

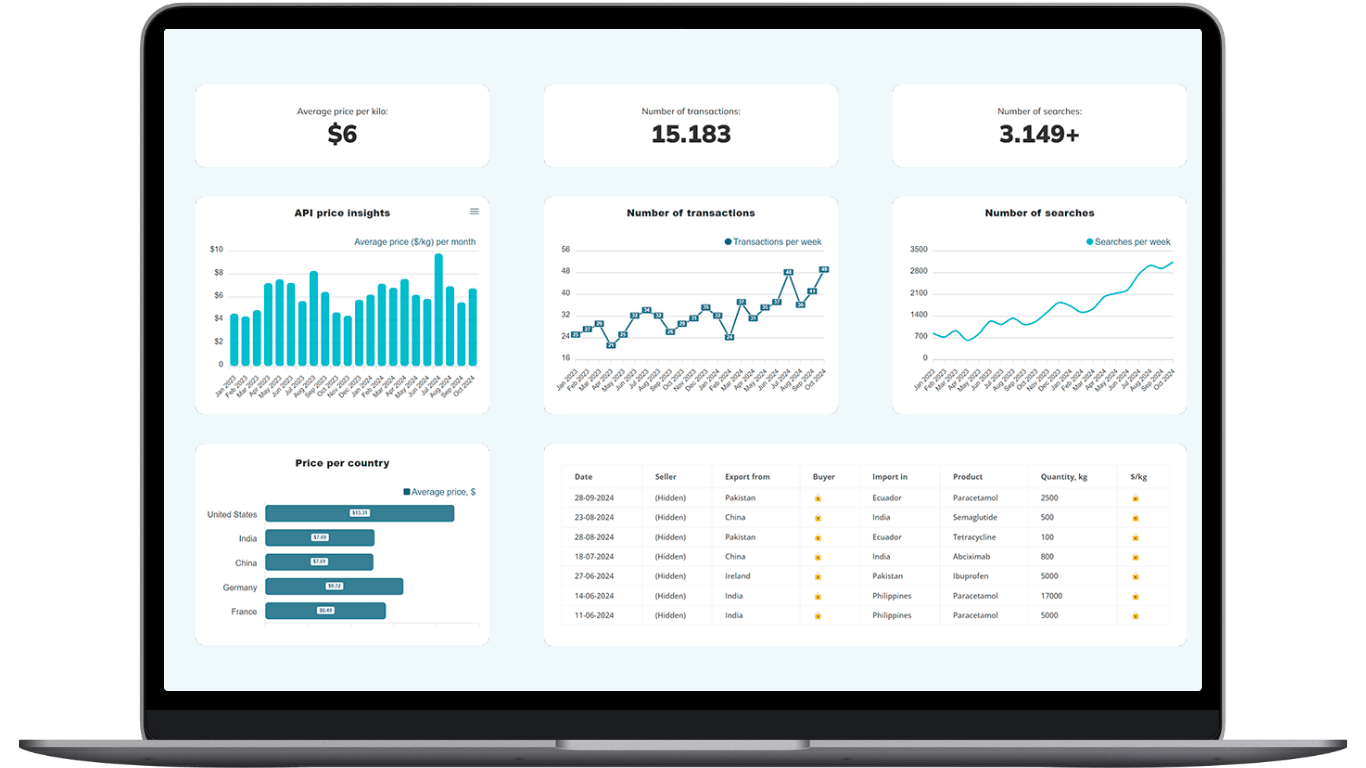

Make Smarter API Decisions with Data

Access exclusive insights on global API pricing, export/import transactions, competitor activities and market intelligence.

What is a CDMO in pharmaceuticals?

A CDMO (Contract Development & Manufacturing Organization) is a third-party partner that develops and produces drug substances (APIs) and/or drug products for pharma companies, helping them scale up and stay compliant.

How do drug substances differ from drug products?

A drug substance is the active pharmaceutical ingredient (API) that delivers the therapeutic effect, while a drug product is the final, patient-ready form—tablets, syrups, creams, injectables—made by combining the API with other excipients.

Why outsource to a CDMO or CMO?

Outsourcing lets pharma companies tap into specialized expertise, GMP-certified facilities, faster scale-up, and global regulatory know-how—reducing cost, time-to-market, and compliance risk.

What types of APIs can CDMOs develop?

CDMOs handle small-molecule APIs, biologics, peptides, oligonucleotides, natural extracts, fine chemicals, and even cell- & gene-therapy actives, all under strict quality standards.

Which dosage forms can CMOs manufacture?

Leading CMOs can formulate oral solids, liquids, semi-solids, ophthalmic, nasal, inhalation products, sterile injectables, and biologic or cell-therapy infusions—covering nearly every modern drug format.

Check out all other blogs here!