What to Ask Your CDMO:Solid vs Liquid Phase Peptide Synthesis

Priya Bhat | Posted on July 10, 2025

When it comes to outsourcing peptide production, one of the most important decisions you’ll face is choosing between solid-phase or liquid-phase peptide synthesis. This choice goes far beyond cost alone—it impacts the scale, purity, cost-effectiveness, and even the technology transfer process.

As you enter into a partnership with a Contract Development and Manufacturing Organization (CDMO), understanding the differences between these two methods is crucial for ensuring that your peptide development aligns with your project goals.

Table of contents

What is a Peptide?

Peptides are short chains of amino acids, which are the building blocks of proteins. They are naturally occurring molecules in the body and have many important functions, such as acting as hormones, enzymes, and neurotransmitters. In the pharmaceutical industry, peptides are often used in drug development because they can have a wide range of therapeutic effects, from cancer treatment to metabolic disorders. Peptide drugs are typically easier to design and manufacture than traditional small molecule drugs, which makes them an appealing option for many pharmaceutical companies.

What is Solid-Phase Peptide Synthesis (SPPS)?

Solid-phase peptide synthesis (SPPS) is a widely used method in peptide synthesis, where the peptide chain is built step-by-step on a solid support material. The process is highly automated and efficient, making it ideal for producing small- to medium-sized peptides. It offers high purity, and the automated approach results in high throughput, making it especially beneficial for fast-paced projects.

What is Liquid-Phase Peptide Synthesis (LPPS)?

In contrast, liquid-phase peptide synthesis (LPPS) involves the peptide chain being synthesized in a solution rather than on a solid support. This method is often used for larger peptides and complex sequences that cannot be easily synthesized using SPPS. LPPS can be more flexible, though it requires more intricate purification methods to achieve the desired purity and yield.

Core Differences:

- Scalability: SPPS is typically more scalable for smaller peptides, while LPPS is often better suited for larger, more complex peptides.

- Automation: SPPS is highly automated, making it a faster and more efficient choice for high-throughput projects. LPPS is less automated and may require more manual intervention.

- Purification: SPPS offers easier purification steps, as the solid support allows easy removal of the peptide. LPPS generally requires more complex purification processes.

- Yield: SPPS often results in higher yield for small to medium peptides, while LPPS can have better yields for larger or more complex peptides, though this varies depending on the specifics of the project.

Impact on CDMO Collaboration:

How Synthesis Method Influences CDMO Selection

When selecting a CDMO, the synthesis method used is a key factor in your decision. Not only does it determine the process for creating the peptide, but it also impacts how your product will be scaled, purified, and ultimately delivered.

Key Factors to Consider:

- Batch Size: Does the CDMO specialize in large or small batches? Choose a partner whose synthesis method and capabilities match the scale you need.

- Complexity: Does your peptide require intricate modifications or large molecular weights? The synthesis method should be selected based on the complexity of your target molecule.

- Budget: Solid-phase synthesis is often more cost-effective for smaller peptides, while liquid-phase synthesis may be better suited for larger, complex peptides despite higher costs.

- Regulatory Requirements: Some regulatory bodies may prefer certain synthesis methods over others based on product purity and batch consistency. Ensure that your CDMO is compliant with the required standards for your peptide.

What to Ask a CDMO

- Which synthesis method do you specialize in—and why?

- Understand why the CDMO prefers a particular synthesis method and whether it aligns with your project’s needs.

- What scale have you achieved using [selected method]?

- Confirm the CDMO’s experience with scaling the method you require. Make sure they have the capabilities to handle the production volumes you need.

- How do you handle purification and impurity profiles?

- Ask about the purification process and how they ensure high purity in the final product. Pay attention to how they handle impurities and how it could affect your timeline and costs.

- Can your site accommodate tech transfer from one synthesis type to another?

- It’s crucial that your CDMO is flexible in case your project requires a shift in synthesis methods during development or scaling.

Choosing the right CDMO for your peptide project is about more than just cost or capacity—it’s about understanding how your peptide will be synthesized and whether your partner’s methods align with your goals. Whether you choose solid-phase or liquid-phase synthesis, working closely with a CDMO that understands your needs and can navigate the complexities of the synthesis process is essential for successful peptide development. Be sure to ask the right questions, evaluate their capabilities, and make an informed decision to set your project up for success.

Looking for the ideal certified CDMO partner to bring your peptide project to life? Explore Pharmaoffer’s network of trusted, certified CDMOs and connect with the right experts for your specific needs. Start your journey today and find the support you need for successful development.

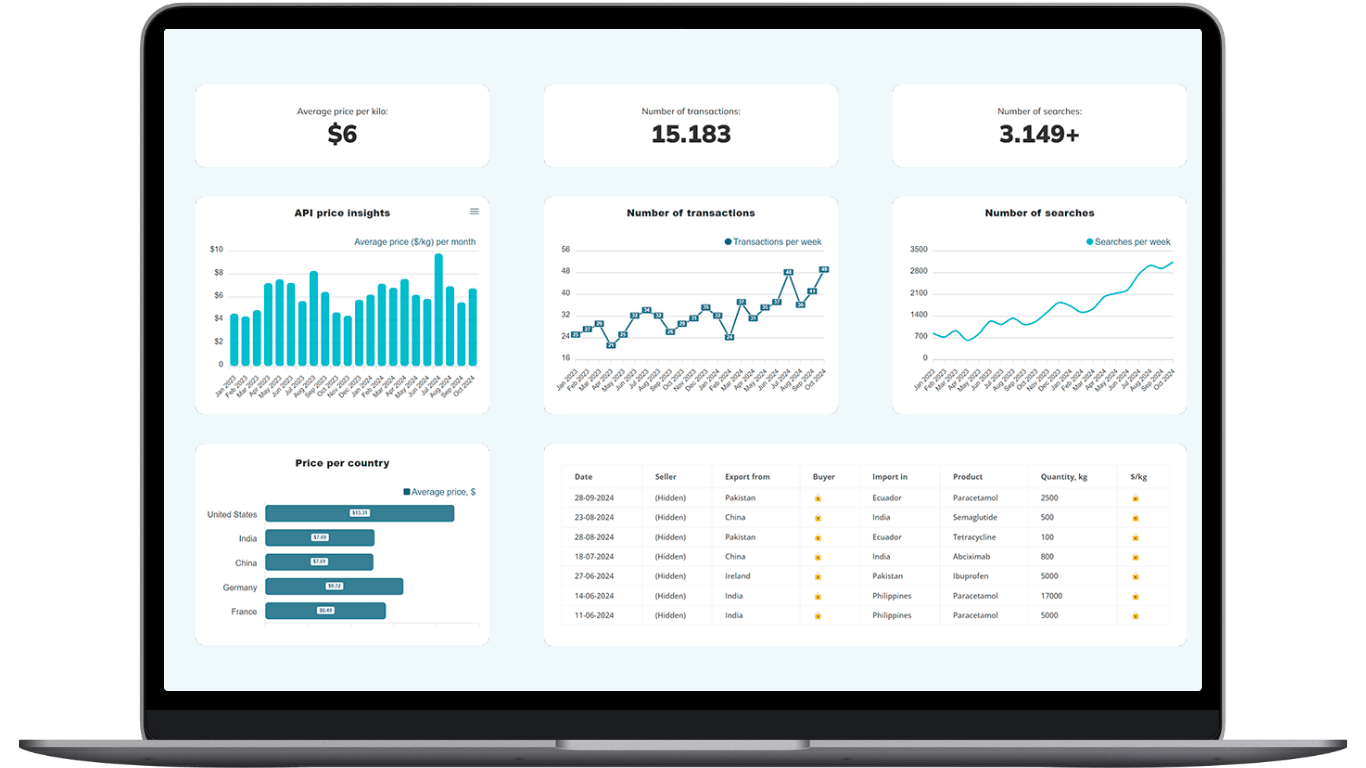

Make Smarter API Decisions with Data

Access exclusive insights on global API pricing, export/import transactions, competitor activities and market intelligence.

Which synthesis method is cheaper for short peptides?

Solid-phase peptide synthesis (SPPS) is usually the most cost-effective for peptides under ~30 amino acids because it is highly automated and has simpler purification.

When should I consider liquid-phase peptide synthesis?

Choose LPPS for longer chains (>40 amino acids) or sequences with difficult modifications where solution chemistry delivers higher yields and flexibility.

Does the peptide synthesis method affect regulatory approval?

Regulators focus on batch consistency and impurity levels. SPPS often meets these requirements more easily for small peptides, but LPPS is fully acceptable if supported by robust GMP analytics at the CDMO.

Where can I find certified CDMOs for peptide manufacturing?

Pharmaoffer’s marketplace lets you filter GMP-, FDA-, and CEP-audited CDMOs worldwide, request quotes, and chat directly with suppliers.

How can digital platforms support my pharmaceutical supply chain needs?

Pharmaoffer’s digital platform connects you with vetted API suppliers, CDMOs, and CROs, simplifying sourcing and compliance checks. Comparing multiple partners in one place saves time, improves supplier reliability, and strengthens overall supply chain efficiency.

Check out all other blogs here!