The particle size of APIs

Why it is Important?

Priya Bhat | Posted on October 5, 2023

Introduction

In the realm of pharmaceutical manufacturing, the adage “size matters” takes on a profound significance, especially when it comes to the particle size of Active Pharmaceutical Ingredients (APIs).

The microscopic dimensions of these crucial components are more than just a technical detail; they are a cornerstone that impacts drug effectiveness, stability, and even the ease of production.

This article unravels the critical role of particle size in the pharma industry, shedding light on its domino effect on drug development and manufacturing processes. Whether you’re a veteran in the field or someone new navigating through, understanding the importance of particle size is fundamental.

So, how does the size of a particle make a significant ripple in the vast ocean of pharmaceutical manufacturing? Let’s delve into the microscopic world of APIs and unfold the big impact of small dimensions.

Understanding Particle Size

Definition and Measurement

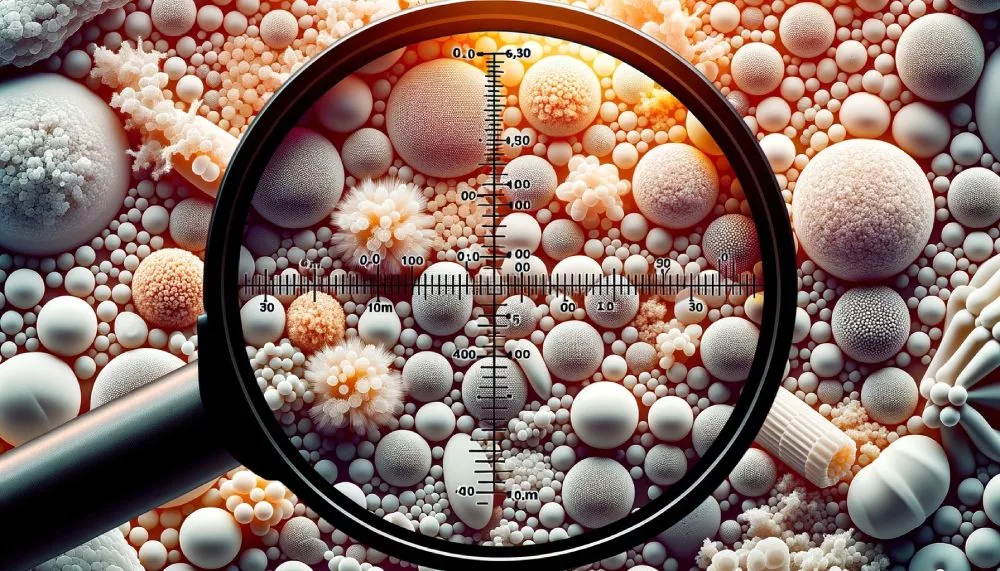

Particle size, as the term suggests, refers to the dimensions of individual particles that comprise a substance. In pharmaceuticals, these particles are often measured using techniques like laser diffraction or dynamic light scattering. The result is often expressed as a Particle Size Distribution (PSD), which gives insight into the size range and the frequency of different size particles in a sample.

Particle Size Distribution (PSD)

PSD is a pivotal parameter in pharmaceuticals. It doesn’t just tell us about the size of particles but also the range of sizes within a sample. This distribution can significantly influence the physical and chemical properties of a drug, its stability, appearance, and performance.

Impact on Drug Development

Solubility and Bioavailability

The journey from a mere chemical entity to a life-saving drug is a meticulous one. A pivotal aspect of this journey is ensuring the drug is soluble and bioavailable. Here’s where particle size steps in. Smaller particles have a larger surface area, which can enhance the solubility and hence, the bioavailability of the drug, making it more effective in its therapeutic action.

Drug Stability and Efficacy

The stability and efficacy of a drug are akin to the two pillars holding the therapeutic promise of a drug. Particle size can influence how a drug interacts within the body and with other substances, thus playing a crucial role in ensuring the drug remains stable and efficacious from production till consumption.

Role in Manufacturing Processes

Compression, Coating, and Granulation

The harmony between particles is not just a microscopic event; it orchestrates the larger dance of drug manufacturing. Particle size affects how materials behave during crucial processes like compression, coating, and granulation, ultimately influencing the quality and characteristics of the final product.

Filtration and Drying

In the labyrinth of pharmaceutical manufacturing, processes like filtration and drying are the unsung heroes ensuring product purity and consistency. The particle size dictates the efficiency and effectiveness of these processes, serving as a critical parameter in achieving the desired product quality.

Techniques for Particle Size Control

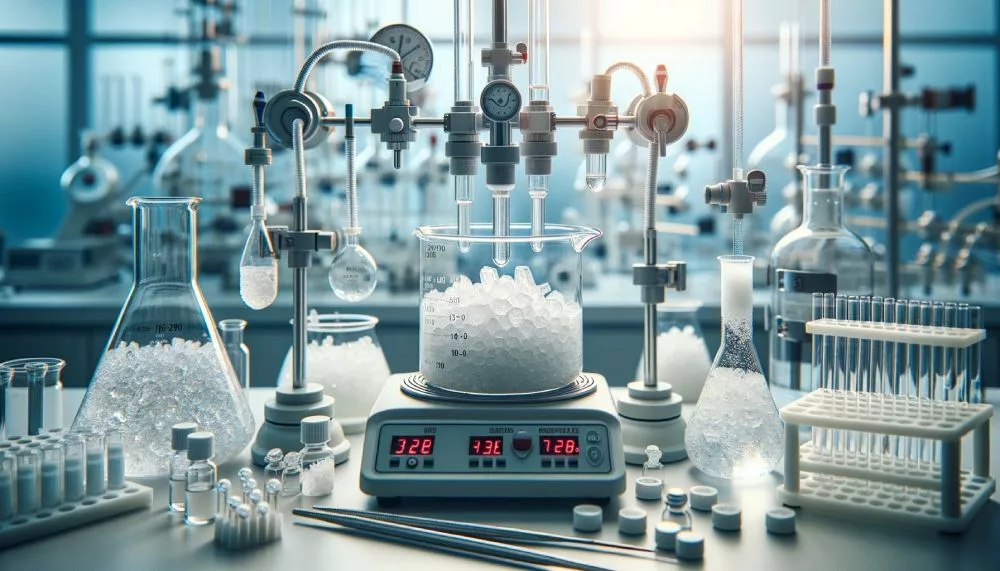

Crystallization

Crystallization is a quintessential method employed to reign in particle size. By meticulously controlling parameters like temperature and agitation rates during crystallization, pharmaceutical manufacturers can influence the size of the crystals formed, ensuring they meet the desired specifications.

Milling/Micronization

Milling and micronization are mechanical methods to achieve the desired particle size. By applying force to break down particles into finer sizes, these techniques offer a way to control particle size post-synthesis, adapting the API to meet the stringent requirements of drug formulation.

Make Smarter API Decisions with Data

Access exclusive insights on global API pricing, export/import transactions, competitor activities and market intelligence.

Challenges and Solutions

Mechanical Size Reduction

Mechanical methods like milling present challenges due to the hardness of crystals or potential damage to the crystal structure, yet they remain indispensable for achieving desired particle sizes.

Real-time Monitoring Technologies

Employing real-time monitoring technologies can significantly mitigate the challenges, providing crucial insights during the manufacturing process and enabling timely adjustments to ensure the desired particle size distribution.

Regulatory Considerations

Quality Control and Compliance

Adhering to quality standards is paramount, and particle size plays a pivotal role in meeting regulatory benchmarks, ensuring that the drugs manufactured are safe, effective, and of high quality.

International Standards

Various international standards stipulate guidelines on particle size and distribution to ensure uniformity and quality across the pharmaceutical landscape, underscoring the global emphasis on precise particle size control.

Advancements in Particle Size Analysis

Innovative Technologies

Emerging technologies are propelling the capabilities of particle size analysis, providing deeper insights and enhanced precision, thus aiding in better control over particle size during manufacturing.

Future Trends

The trajectory of technological advancements hints at even more sophisticated tools on the horizon, which would further demystify the microscopic realm of particles, paving the way for enhanced drug development and manufacturing.

Benefits of Optimal Particle Size Control

Improved Drug Delivery

Optimal particle size control translates to improved drug delivery, ensuring that the therapeutic benefits of the drug are fully realized by the body.

Cost Efficiency

Efficient control over particle size not only enhances drug quality but also drives cost-efficiency in the manufacturing process, making it a win-win scenario for both manufacturers and consumers.

Real-world Implications

Case Examples

- Enhanced Drug Delivery: A pharmaceutical company managed to significantly improve the bioavailability of a crucial medication by fine-tuning the particle size of its active ingredient, thereby ensuring more effective treatment for patients.

- Cost Reduction: By optimizing particle size, another company was able to streamline its manufacturing process, resulting in notable cost savings without compromising the quality of the final product.

Lessons Learned

- Investment in Technology: Companies that have invested in advanced particle size analysis and control technologies are reaping benefits in terms of product quality and operational efficiency.

- Collaboration: Cross-industry collaborations have led to innovative solutions in particle size control, showcasing the importance of collective efforts in overcoming technical challenges and advancing the field.

Conclusion

Recapitulating the core insights, we’ve unearthed the critical role of particle size in the pharmaceutical arena. Its meticulous control is not just a technical requisite but a linchpin for drug efficacy, safety, and manufacturing efficiency.

FAQ

How is particle size measured in the pharmaceutical industry?

Particle size is often measured using techniques like laser diffraction or dynamic light scattering which provide a Particle Size Distribution (PSD) detailing the range and frequency of different size particles in a sample.

Why is Particle Size Distribution (PSD) important?

PSD is crucial as it influences the physical and chemical properties of a drug, its stability, appearance, and performance.

What techniques are employed for particle size control?

Techniques such as crystallization, milling, and micronization are employed to control particle size.

How does particle size affect drug solubility and bioavailability?

Smaller particles have a larger surface area which can enhance solubility and hence, the bioavailability of the drug.

What challenges are faced in mechanical size reduction for particle size control?

Challenges include potential damage to crystal structure and the hardness of crystals which might hinder achieving the desired particle sizes.

Check out all other blogs here!