Facilities

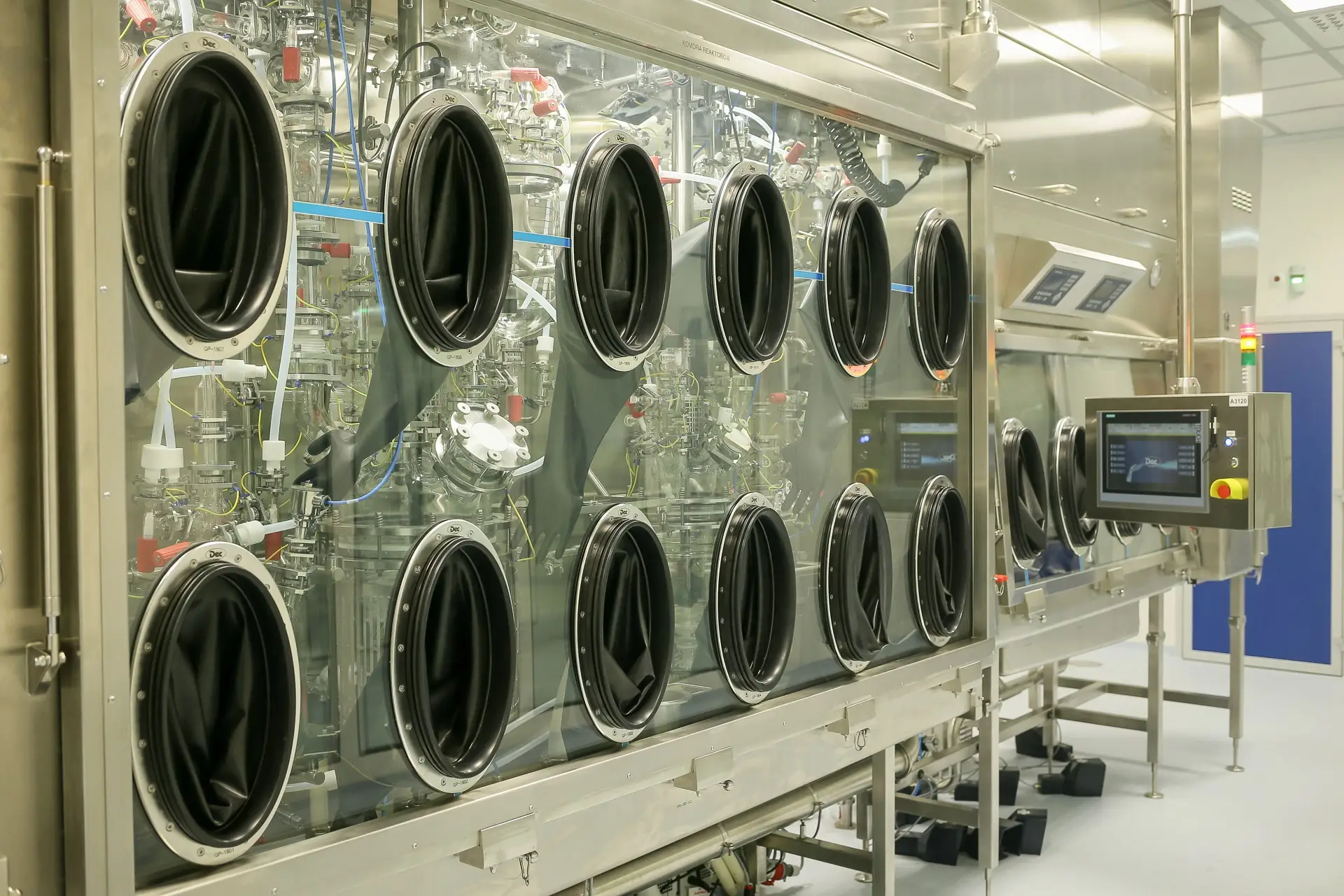

Our Pilot Plant is an independent, small scale FDA approved production facility counting more than 25 reactors and vessels from 50 to 650 L for a total of 6 m3 capacity.

3 different and fully segregated clean zones for final APIs processing enable 3 parallel projects to run independently. Pilot Plant operations are designed and maintained an exactly the same standard as the production environment at the target commercial scale, which ensures a smooth process transfer at a larger...

Latest updates

Ryvu Therapeutics and Polpharma sign two agreements in the area of RVU120 API production for Phase II clinical trials

Ryvu Therapeutics (WSE: RVU), a clinical-stage drug discovery and development company focusing on novel small molecule therapies that address emerging targets in oncology and Zakłady Farmaceutyczne Po

Learn more

Another Polpharma API strategic milestone achieved!

Another Polpharma API strategic milestone achieved! ‍ KiloLab Laboratory - a development and production in a kilogram scale - has been launche

Learn more

First CADIFA certification from ANVISA for Etodolac

In the dynamic landscape of pharmaceutical regulations, Brazil took a significant stride in April 2020 when ANVISA unveiled new rules about active pharmaceutical ingredients (APIs). Fast forward to Au

Learn more

Rising Prevalence of Cancer and Its Impact on the HP API Market

Cancer cases are expected to increase by 61% by 2050, particularly in lower-income countries. This alarming trend underscores the urgent need for more effective and targeted treatment options. In resp

Learn more

Polpharma Group's environmental responsibility

We understand that a healthy world that we strive to contribute to through our mission includes a healthy environment. As a manufacturing company, we are committed to reducing our environmental impact

Learn more

An Overview of Breast Cancer: Understanding Risks, Treatments, and Market Trends

Breast cancer is a disease characterized by the uncontrolled growth of cells in the breast tissue. It is the second most common cancer type overall, and the most prevalent cancer among women worldwide

Learn more

Polpharma's HP API facility is live!

An extraordinary investment in the API sector - a new facility adapted to work with highly potent active pharmaceutical ingredients (HP API), the first and only of its kind in Poland.

Learn more

Addressing Nitrosamine Risks in Pharmaceutical Manufacturing

In the relentless pursuit of excellence and delivering top-quality products, the pharmaceutical industry often relies on established facts and practices. However, thi

Learn more

A Comprehensive Overview and Prognosis of the Diabetes Market

Diabetes is one of the most serious health problems in the modern world.

Learn more

Welcoming Pere Mañé as Suanfarma’s New CEO

Suanfarma Appoints Pere Mane as New CEO to Drive Industrial Growth and Global Expansion

Learn moreUpcoming events

DCAT 2025

In-person event17-03-2025

World ADC London 2025

In-person event03-03-2025

World ADC San Diego

In-person event03-11-2025

CPHI WW 2025 Frankfurt

In-person event28-10-2025

CPHI China 2025

In-person event24-06-2025

Services

- New chemical routes full development

- Process optimization

- Technical transfer

- Analytical methods development, transfer, validation

- Troubleshooting

- Crystallization studies

- Particle size distribution control

Our Pilot Plant is an independent, small scale FDA approved production facility counting more than 25 reactors and vessels from 50 to 650 L for a total of 6...

Drug Substance (CDMO/CRO)

Replies quickly

Replies quickly

Replies quickly

Replies quickly

Replies quickly

Contact Polpharma for Contract Services Expertise

Connect with Polpharma, a leading pharmaceutical company from Poland. They offer specialized Drug Substance (CDMO/CRO). Contact Polpharma for free and discover if they are the perfect partner for your pharmaceutical needs.

Drug Substance (CDMO/CRO)

Drug Substance CDMOs and CROs provide essential services in the development and manufacturing of active pharmaceutical ingredients (APIs). These organizations specialize in early-stage research, process development, and GMP-compliant manufacturing of drug substances for clinical and commercial use.

Pharmaoffer's Drug Substance CDMO/CRO category includes partners with expertise in small molecules, biologics, peptides, and complex chemistry, all operating under strict regulatory compliance. These providers help companies scale from lab to market efficiently and cost-effectively.

Key Functions of Drug Substance CDMOs/CROs:

API Research and Development: Providing early-stage discovery support, custom synthesis, and process optimization to streamline the development of drug substances.

Process Scale-Up and Tech Transfer: Transitioning from bench-scale to pilot and commercial scale production with validated methods and reproducibility.

GMP Manufacturing: Delivering high-quality API batches in GMP-certified environments, adhering to FDA, EMA, and other international standards.

Analytical Services: Offering comprehensive analytical method development and validation to ensure consistent quality and regulatory compliance.

Flexible and Specialized Capabilities: From small molecule synthesis to biologic and peptide manufacturing, these partners provide specialized services tailored to product-specific needs.

Explore Leading API CDMOs and CROs

Pharmaoffer connects you with trusted CDMOs and CROs for drug substance development. Our platform enables seamless access to specialized service providers equipped to support your API lifecycle from discovery to commercialization.

Show all images

Show all images

Follow us:

Follow us: