The impact of the API

on the cost price of generic medicine

By: David Blok | Posted on January 3, 2023

Introduction

Life is getting more expensive; just look at the gas prices worldwide, inflation, and shortages of starting materials. The pharma industry is no exception, as the entire supply chain is affected. It’s just a matter of time before we will notice price increases.

If we take a pill that now costs $1. What would happen if the price of the API inside this pill would increase by 40%? Does the entire pill become 40% more expensive?

The answer is no. But to better understand why not, we need to know what the price of medicines consists of.

For the development of new medicine, pharma companies need money for R&D, but for this article, we decided to zoom in on the costs of generic medicines, so medicines of which the patent has expired.

We’ll break down the prices so we know what part of the ingredients account for what part of the costs and find out together the impact of the API on the cost price of a medicine.

Back to basics

First, back to basics. What was an API again? The API is the ingredient in the medicine that is the active part, the one that does the healing. Besides containing an API, a drug consists of excipients, and it costs resources to produce, store, ship, and make some profit.

Breaking down the cost price of drugs isn’t easy. Medicine producers usually aren’t thrilled to share exactly what they paid for an API, the other ingredients and production costs. So we will set up an example case and then break down all the relevant costs.

In a publication from 2018 by scientists from the University of London, Liverpool and Harvard, research was done on the production costs and potential prices for insulin-related medicine.

By contacting API manufacturers, they were able to get an insight into the price of their specific API was, and they also researched other costs such as the formulation, manufacturing process, the excipients and other elements that impact the price.

But to better understand what costs what, we will set up an example medicine production line together:

The cost of API

The prices of an API can fluctuate a lot per producer. You’d think that the better qualified the producer, the more expensive the API. But on our platform, we’ve seen prices for the same API be quite far apart for the same qualifications. The price difference can be thousands of dollars per kg. Also, for example, when there is a distributor or an agent in between.

But in general, the price of the API depends on the batch size, the country where it was produced, the quality system the producer has, what their profit margins are, and also if the buyer of the API perhaps is a well-known customer to them who frequently also buys other APIs from them resulting in a discount.

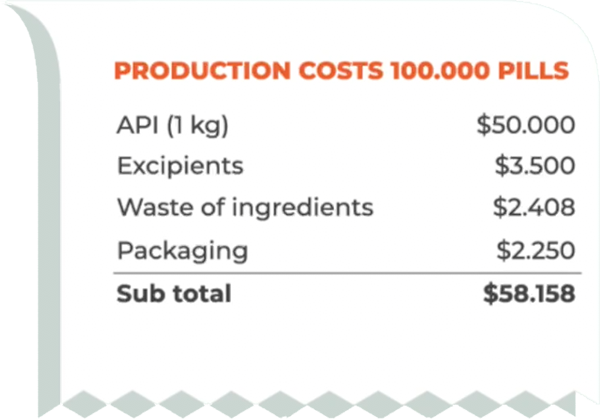

Let’s say we have an API that we bought at $50.000 per kg. To make 100.000 pills that contain 10 mg of the API, we need 1 kilogram of the API, so that’s $50.000 for 100.000 pills. By the way, we made a video about how to get better deals with API suppliers; you should check it out.

The cost of excipients

Then we have the excipients. Excipients are the ingredients that support the API, for example, as a bulking agent, as flavoring, or to act as a stabilizer and, thus, the drug’s shelf life. It depends on the medicine, which excipients you need, and how many, but in our example, it is $3.500 for the 100.000 pills.

Loss of ingredients during formulation

Unfortunately, during formulation, you will waste some of the ingredients. For instance, you must take samples for quality regulations or because some material sticks to the packaging. Same as with you at home, you can probably never finish a ketchup bottle cleanly; some will always be left in the bottle.

And spills or errors can lead to an average norm of 4.5% waste of the API and excipients during formulation. So we’ll add that to our production costs so far.

Cost of materials and formulation

Then, you need something to put all of this in. Containers to put tablets in, empty capsules to fill with powder, vials to put liquids in, so basically a packaging method of choice that is most convenient for the end user.

In our example, we’re talking about $2.250 for primary packaging for our 100.000 pills.

Logistics/warehousing

When the pills are finished, they don’t get shipped to the customer or end users the same day. You need to store them in a warehouse, sometimes for months. And not all can be kept in a plain warehouse; perhaps they need to be stored cold. And there are many checks by the quality control department and the warehouse people before you can ship out the drugs.

And then, when you can finally send them out, there are costs for the secondary packaging such as boxes, pallets, filling material, document costs, and labor costs…. On average, it adds 20% to the price we’re on so far.

Operating margin & go to market

The final chunk of the costs is in the operating margin, a.k.a. the profit, and the costs of going to market, such as getting authorized, marketing, and having the proper documents to go alongside your medicine.

The operating margin is an average of 20%, and the go-to-market costs are estimated at around 25%.

Our price breakdown is now complete; let’s round up all these numbers and put them in a pie chart:

As you can see in the chart above, the API generally accounts for 52% of the cost price of the drug.

The 100.000 pills we produced, we were able to do that for a little over $95.000, whereas the API cost us $50.000.

So if the price of the API increases by 40%, does the new price of the drug become around $130.000? Most likely not, as the prices of the excipients, packaging, and formulation remain the same. As the price of the API is “only” about half the price of the cost in the end, a 40% increase in the API will lead to around a 20% increase in the total price.

But on the other hand, if you find a 40% cheaper source for the API, for example, by contacting different suppliers, it also means that the cost price of the medicine becomes 20% less, which would save you about $20.000 bucks. It’s up to you if you want to lower the selling price. Or go to Disneyland with the whole company.

There are still lots of other parameters that affect the price, of course. Such as the scale of your production, producing 500 pills by hand or 10 million by machine, there’s a difference in the cost of production. And by buying 500 empty capsules or 10 million, you can guess where you’d get a better deal per capsule.

But this was to give you a general idea about the impact of the price of the API on the cost price of the entire drug!

Thank you for reading.

FAQ

What is an API and how does it affect the cost of generic medicine?

API stands for Active Pharmaceutical Ingredient. It's the component in medicine that carries out the healing or treatment. APIs significantly impact the cost of generic medicine, accounting for about 52% of the overall price.

Does an increase in API cost make the medicine 40% more expensive?

A 40% decrease in API cost could lead to about a 20% decrease in the total price of the drug. You could pass the savings on to consumers or reallocate those funds for other business purposes.

What other elements contribute to the cost of a generic drug?

Apart from the API, costs like excipients (supporting materials), production, packaging, and logistics also contribute. These include costs for formulation, primary and secondary packaging, and warehousing.

Check out all other blogs here!